COGNITO: Activity Monitoring and Recovery

Ardhendu Behera, David Hogg and Anthony Cohn

Motivation

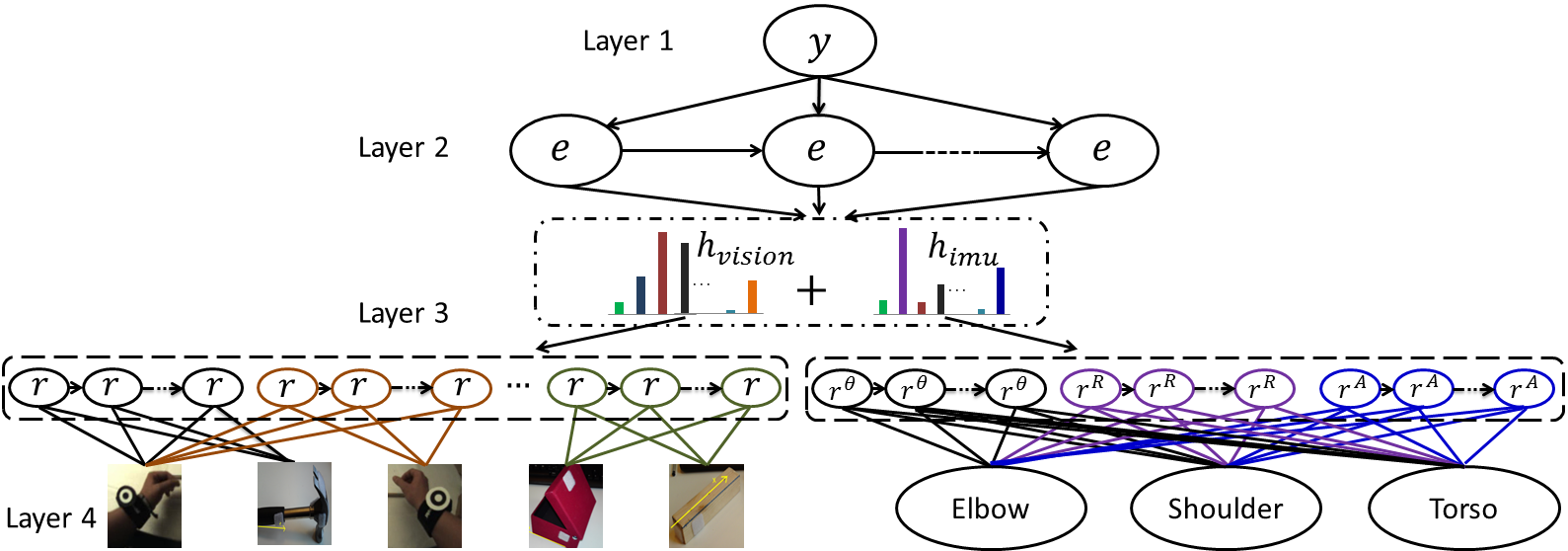

Most of the existing approaches for activity recognition are designed to perform after-the-fact classification of activities after fully observing videos of single activity. Moreover, such systems usually expect that the same number of people or objects are observed over the entire activity whilst in realistic scenarios often people and objects enter/leave the scene while activity is going on.There are three main objectives of the proposed activity recognition system: 1) to recognise the current event from a short observation period (typically two seconds); 2) to anticipate the most probable event that follows on from the current event; 3) to recognise activity deviations.

Publications

|

A. Behera, D. C. Hogg and A. G. Cohn, Egocentric Activity Monitoring and Recovery (ACCV 2012).

pdf

Demos: labeling and packaging bottles and hammering nails and driving screws |

|

A. Behera, A. G. Cohn, D. C. Hogg. Workflow Activity Monitoring using the Dynamics of Pair-wise Qualitative

Spatial Relations. International Conference on MultiMedia Modeling (MMM 2012) (Oral).

pdf

Demos: driving screws and

hammering nails

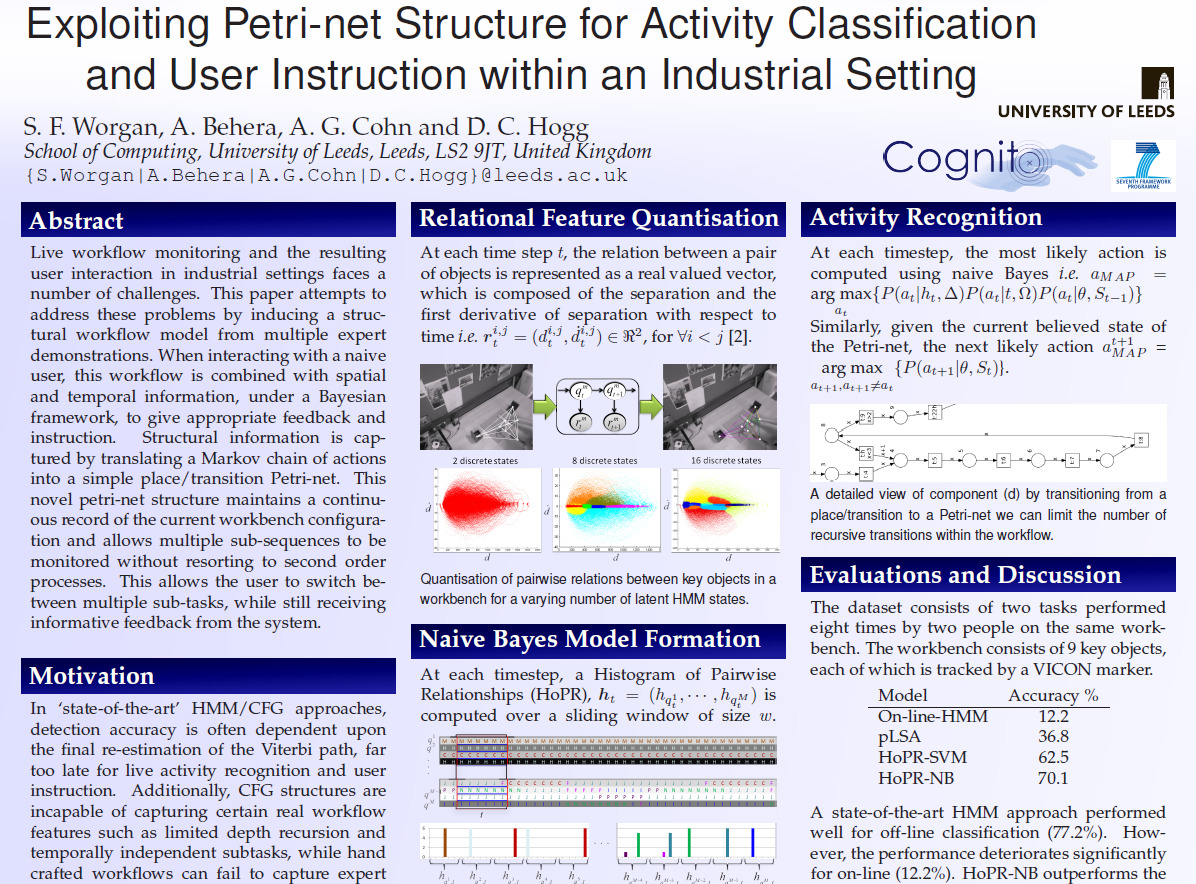

| S. F. Worgan, A. Behera, A. G. Cohn, D. C. Hogg. Exploiting petri-net structure for activity classification and user instruction within an industrial setting. International Conference on Multimodal Interaction (ICMI 2011). pdf |  |

Datasets

In order to test our hierarchical framework, we have obtained two datasets using an egocentric setup. These datasets consist of non-periodic manipulative tasks in an industrial context. All the sequences were captured with on-body sensors consisting IMUs, a backpack-mounted RGB-D camera for top-view and a chestmounted fisheye camera for front-view of the workbench.The first dataset is the scenario of hammering nails and driving screws. In this dataset, subjects are asked to hammer 3 nails and drive 3 screws using prescribed tools.

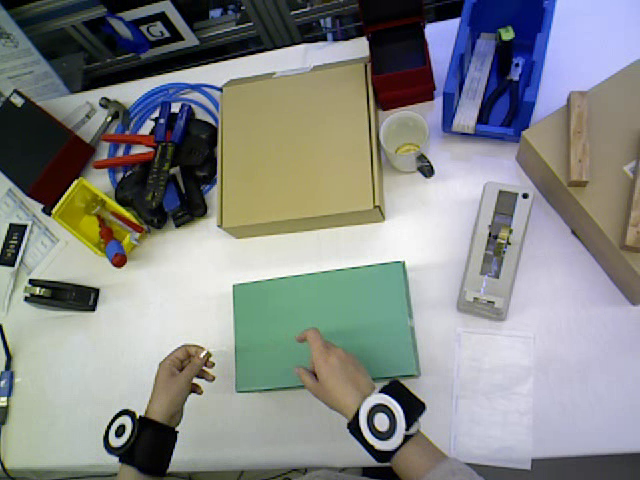

The second dataset is a labelling and packaging bottles scenario. In this dataset, participants asked to attach labels to two bottles, then package them in the correct positions within a box. This requires opening the box, placing the bottles, closing the box, and then writing on the box as completed using a marker pen.

Hammering three nails and driving three screws

|

|

|

|

The dataset consists of videos from both views, object tracklets (3D positions), upperbody model (IMU) and ground-truth. The top view video sequences (~0.7 GB) and front view sequences (~0.6 GB) are available. Object and wrist tracklets, and IMU data (upperbody model) and activity labels are available here (~80MB).

Labelling and packaging bottles

|

|

|

|

The dataset consists of videos from both views, object tracklets (3D positions), upperbody model (IMU) and ground-truth. The top view video sequences and the activity labels are available here (~1.7 GB). Objects and wrist tracklets, and IMU data (upperbody model) can be found here (~100MB).